Used mainly in the Laboratory, they allow accurate measuring of the effects of corona treatment.

- Apply a thin layer of liquid, using the supplied brush, on a surface of 5/7 cm of the treated part of the sample

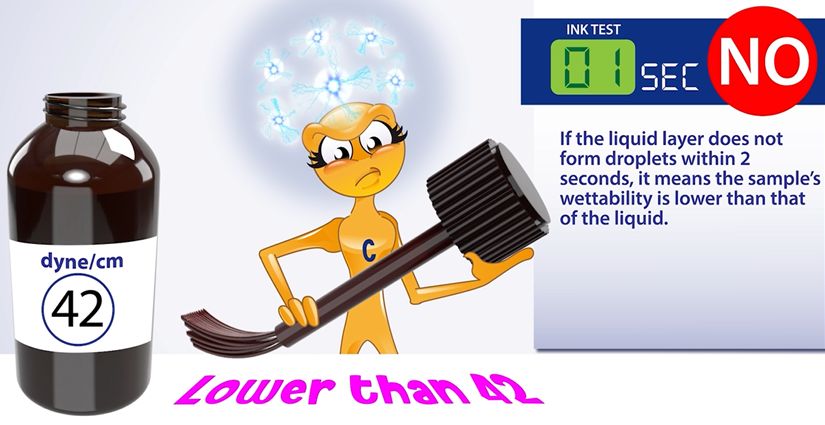

- Measure the time taken by the liquid to divide into droplets.

If the layer of the surface liquid has not changed after two seconds, it means that the wettability of the sample is greater than the value of the fluid used.

To determine the exact value of wettability use a higher value solution:

- if it stays stretched out for two seconds, the wettability of the film corresponds to the value indicated by the liquid used for testing

- if the liquid is divided into droplets in less than two seconds, you should use a of lower value solution.

Ferrarini & Benelli certifies that the dyne/cm values are exactly corresponding to the mixture of Formamide and Cellosolve made according to ASTM D procedures 2578-84. This certification is supported by sample checks carried out using a higher-class device known as "contact angle meter".

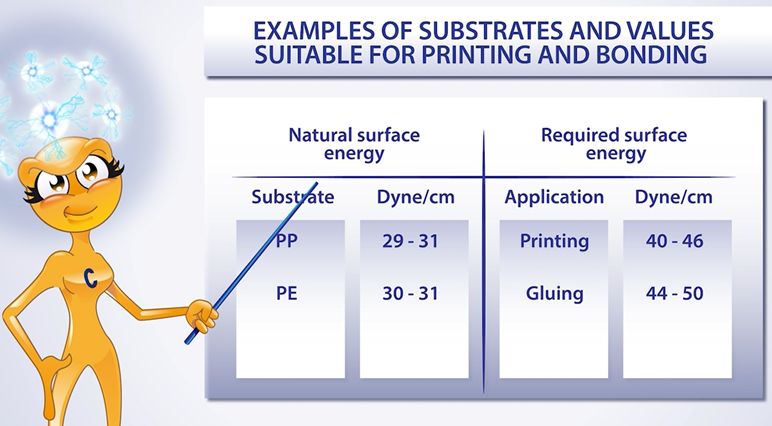

Values of reference (dyne / cm)

For the inks the available values are 31 - 58 dynes / cm

Directions for use

Always keep the bottle closed because the cellosolve tends to evaporate thus changing the composition of the mixture.

The date of expiry of the liquids is not easily quantifiable, because it depends on how much you leave it open to air. To guarantee a perfect measurement it is advisable to replace Test Inks every six months.