Raw materials

The traditionally extruded materials are: polyethylene (HDPE, LDPE and LLDPE) and other raw materials such as PP, PA, EVOH used as barrier or binders in the multi-layer structures. The selection of the number of layers depends on the features required for the different applications (barrier/non-barrier effect, cold resistance...).

Why corona treatment?

The corona treatment increases the surface tension of the plastic films generally inert and non-porous. Among the various plastic films, polyethylene and polypropylene are those that have the lowest surface energy and are, therefore, subjected to corona treatment to improve their adhesion characteristics.

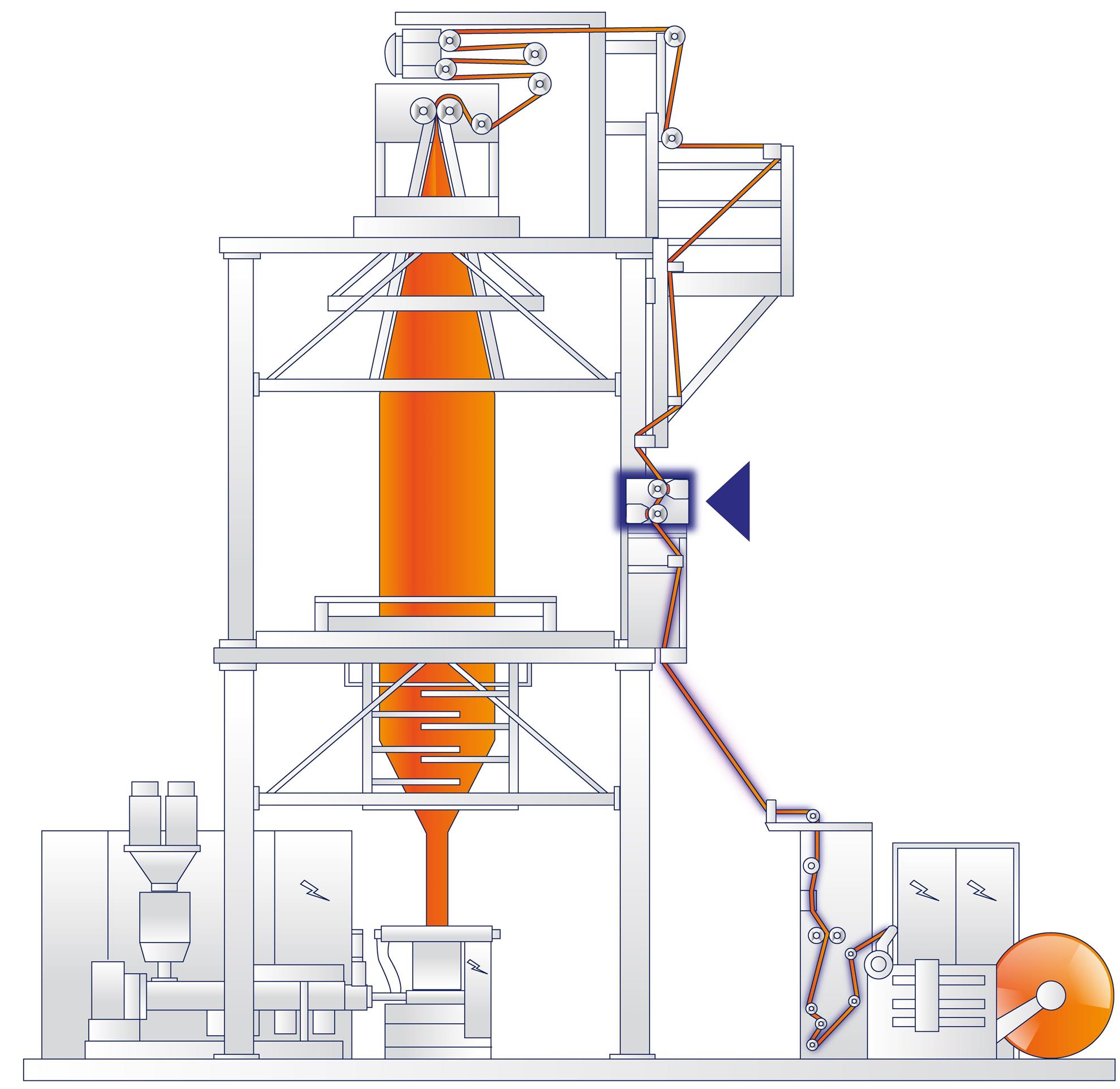

The purpose of using the corona treatment in blown film extrusion lines is that to prepare the film for the subsequent printing, coating and laminating, rolling phases, etc...

The film layer affected by the corona treatment is the outer one, it can be treated both inside and outside the blown film according to a correct positioning of the machinery in the extrusion line to provide both single-treated and double-treated reels.

Applications

We have studied corona treatment machinery for each application!

For example, if the film produced by extrusion is intended for the food packaging sector and it must be printed, the effect of the corona treatment on the entire outer surface of the blown film is to improve wetting by favouring the bonding of the inks.

Another example is the use of the corona treatment on the blown film extrusion line to prepare the film for the subsequent coating phase, obtaining a single-treated reel with improved bonding properties.

In both cases you can install the BIKAPPA ROTARY that allows treating the entire film surface, it adapts to different line speeds.

Whereas, if it is necessary not to treat certain film areas, for example at the welding points for the production of bags, you can install the BIKAPPA ROTARY equipped with segmented electrodes.

In order to print a logo on a small part of a large film, such as for example the logos or markings on tarpaulins in agricultural applications, you can position the TM STRIPE model in line with ink jet printing.

The bio-based and biodegradable materials (Mater-Bi) made up of renewable polymers are often used in the packaging sector; they can treated like polyethylene, react well to corona discharge and require lower powers.

Packaging for fast-moving consumer goods

Flexible packaging films

Rolled films (e.g. aluminium or paper rolls used for packing milk or coffee)

Barrier films (made up of raw materials such as polyamide and EVOH that act as barrier for aroma and oxygen used for food packaging, e.g. meat and cheeses)

Film for frozen food packaging

Film for wrapping food

Elastic films for transport packaging

Film for transport bags

Film for waste bags

Biodegradable films and with recycled raw materials

Film for compressed bags

Film for filling and sealing packaging

Industrial packaging

- FFS film tube for heavy-duty sacks

- Shrink hoods

- Shrink film

- Film for bags

- Film for coatings

- Construction film

Agricultural sector

- Film for greenhouses

- Film for tunnels

- Mulching films

- Silage cover films

- Silage tubes

Technical film

- Technical film

- Film for labels

- Film for surface protection

- Film for healthcare (Backsheet film)

Positioning of the corona treater on the blown film extrusion line: double-sided treatment