In the cast extrusion process one or more layers of polymers are extruded through a flat head chain and placed on rollers that are water cooled (chill roll). The film then passes through a series of rollers which determine the film properties, including thickness. The extruded film will be subsequently cut according to specifications.

Raw materials

The polymers used are: LDPE, LLDPE, mLLDPE, HDPE, PP, CPP, OPP individually extruded or combined to obtain single-layer or multi-layer films (up to 9 layers) with thickness from 15 to 100 µm. Other raw materials such as EVOH, PA6 can also be added to give the film specific properties such as barrier effect, high transparency, good sealing and resistance to perforation.

Why corona treatment?

The corona treatment in cast extrusion lines allows you to increase the surface tension of plastic materials to prepare them for subsequent processing (printing, coupling, adhesive coating, etc.). The presence of additives and lubricants decreases the wetting properties of the film, therefore, it is advisable to install a corona system on the cast extrusion line so as to achieve the desired level of surface tension.

Applications

The films obtained through cast extrusion have a wide range of applications: in the agricultural sector, in the food sector as film barrier for packaging, rolled film for packaging liquids, for disposable sanitary products, gift paper. We study solutions for each application!

- For films intended for the packaging sector the corona treatment, by increasing the surface tension, favours the bonding of inks in the subsequent printing process.

- For films intended to be coated (e.g. rolled films for packaging liquids and/or film barrier), the corona treatment increases the adhesion of glues and adhesives, preventing layer delamination.

The Ferrarini&Benelli corona treatment systems allow treating the entire surface of the extruded film or only a part thereof.Our machinery adapts to the different line speeds, ensuring high performances.

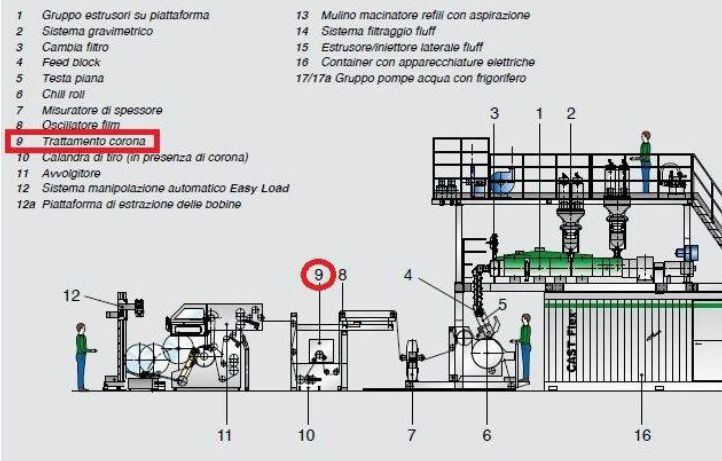

Positioning of the corona treater on the cast extrusion line

The corona treater is positioned downstream of the production line.