BIKAPPA ROTARY 120

For all applications of blown film extruder with width up to 2800 mm.

BIKAPPA ROTARY 150

With big diameter rollers for wide width and strong tension

BIKAPPA ROTARY 200

For large widths from 3000 mm up to 4000 mm (production of thermo-shrinking film or agricultural films)

BIKAPPA ROTARY PRINTING STEP

For applications on extruders with in line flexographic presses: allowing for treatment intermittently synchronised with the print on both sides

BIKAPPA POLIMETAL

Version with ceramic electrodes for the treatment of conductive materials in the printing and laminating processes

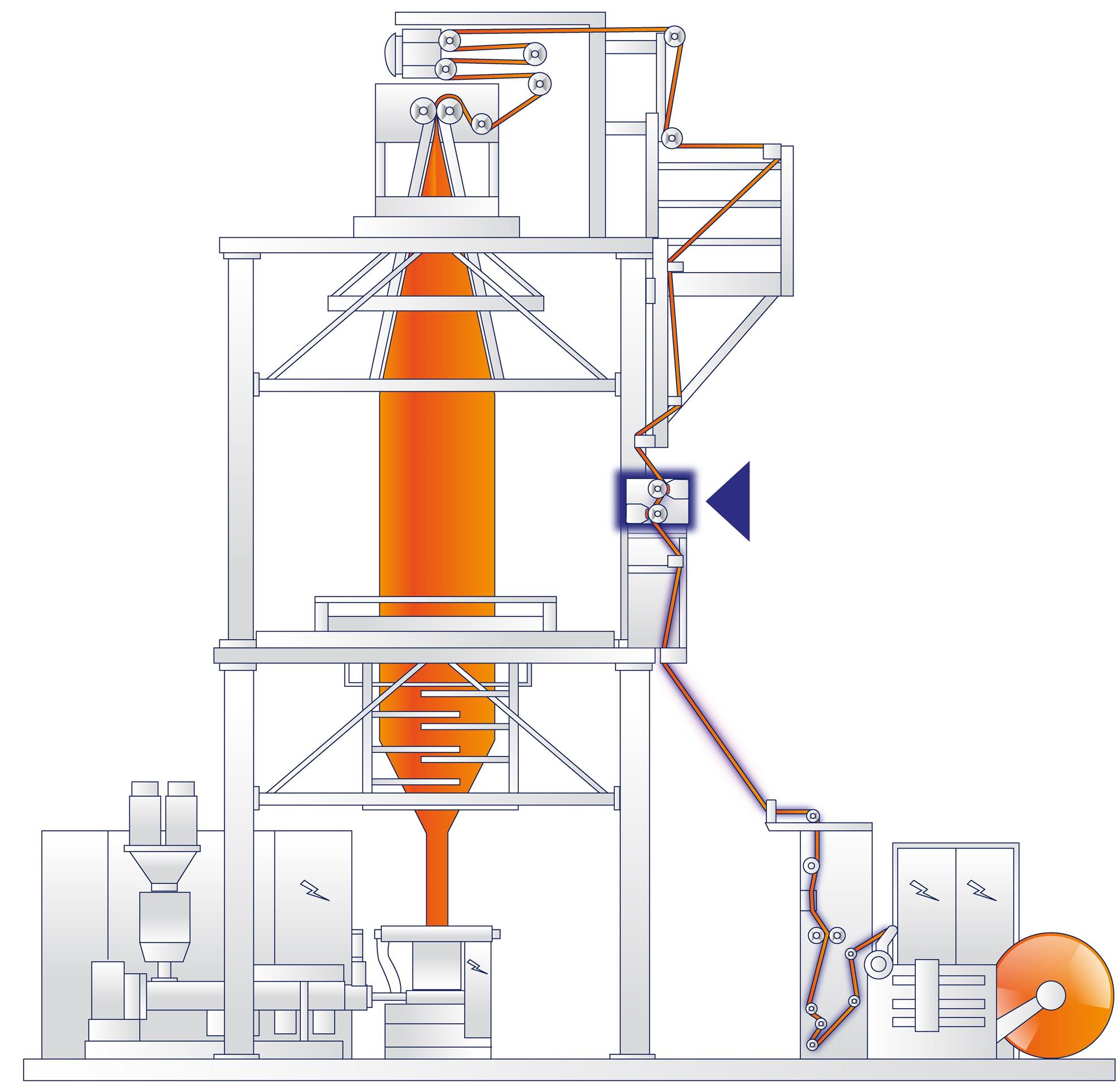

Blown film extruder with Bikappa Rotary treatment system

Blown film extruder with Bikappa Rotary treatment system