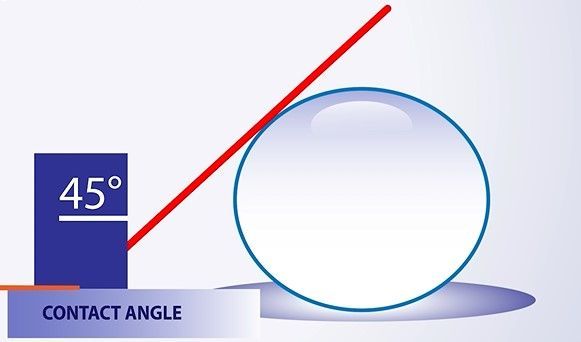

The contact angle is formed on the line that defines the surface of adhesion between a drop of liquid and a solid.

- Complete wettability is obtained when the contact angle approaches 0° and the liquid is completely "spread out"

- Poor wettability is instead obtained when the contact angle approaches 180° and the liquid forms drops.

How to obtain the correct surface tension

Plastic films generally have chemical inert and non-porous surfaces with low surface tensions that make them not receptive to the adhesion of substrates such as printing inks, adhesives and coatings.

Corona treatment systems, to increase the wettability and adhesion characteristics, apply on the surface to be treated a certain power for a defined period of time.

The surface energy, measured in dyne/cm, must be at least 10 dyne/cm higher than the superficial tension of the liquid that you want to apply.

Given that the materials or substrates react differently to the corona treatment and that the result depends on three variables (power applied, line speed and amount of electrode) it is very useful to use Dyne Test Test or Dyne Ink Pen to measure, with different levels of detail, the surface tension of the materials.

For a thorough and timely verification of corona treatment, Ferrarini & Benelli has also developed the software “Corona Quality Control”