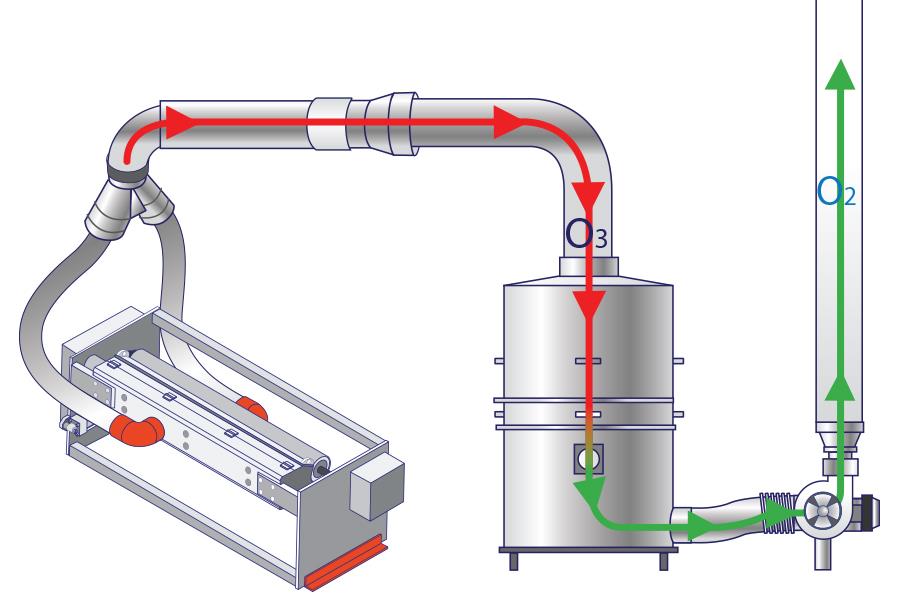

How does it work

The ozone is introduced in the destruction system where a complex of catalysts reduces it to oxygen. The process occurs at room temperature, since the granules of the catalyst, through the use of particular precious metals, do not need energy to cause the reaction.

The multi-stage catalytic destruction system Ozo-no! is composed of:

- P200 pre-filter (polyester)

- filter "C"

- catalyst.

Since ozone is a highly oxidising element, installing ducts with rustproof materials (plastic or stainless steel) is recommended: do not use galvanised metal.

Advantages over other destruction systems

- Smaller size compared to activated charcoal models (1/6 in volume)

- Very high destruction efficiency

- Very high durability (if inlet filter is cleaned or changed periodically so that the catalyst is not clogged with dust or polyolefins, durability is almost unlimited)

- Electricity savings (compared to activated charcoal destruction systems, less powerful fans are used, given that the volume of the catalyst is 6 times less than that of activated charcoal)

- Routine maintenance is very economic

- With ceramic electrodes and power exceeding 5 kW, normal activated charcoal destruction systems fail to meet the legal threshold.

The Ozo-no! catalyst doesn't have any combustion problems.

Regeneration of catalysts

If your catalyst has decreased efficiency because of contamination, do not replace it!

The catalyst regeneration service provided by Ferrarini & Benelli allows for significant cost savings and eliminates the problem of disposal.

|

|

RANGE Q (m³/h)

|

|

OZO-NO! C40

|

4000

|

|

OZO-NO! C30

|

3000

|

|

OZO-NO! C20

|

2000

|

|

OZO-NO! C12

|

1200

|

|

OZO-NO! C06

|

600

|

|

OZO-NO! C04

|

400

|

| OZO-NO! |

200 |